What is Additive Manufacturing?

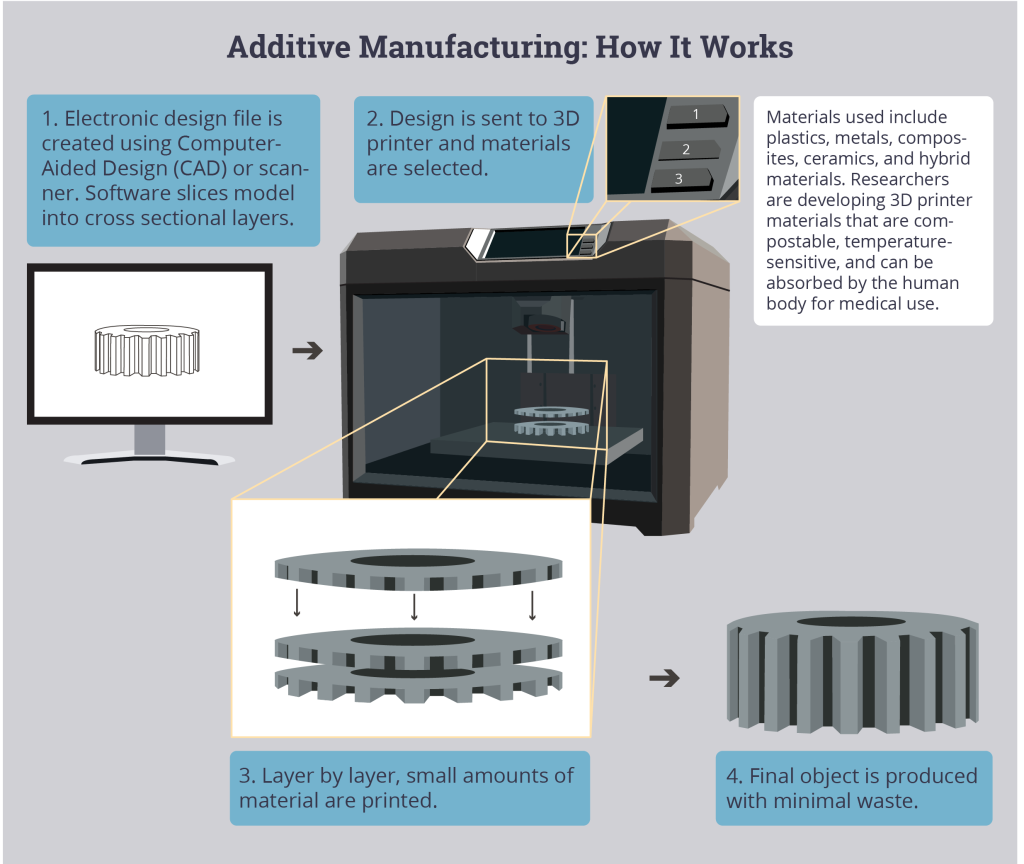

Additive manufacturing, commonly known as 3D printing, is the process of connecting (“adding”) successive layers of various substances—such as plastic polymer or metal—closely over one another, which creates a usable 3D version of whatever is being modeled. Using computer-aided design (CAD) software, products ranging from ear buds to jet engine fuel nozzles to medical implants, can be modeled and printed, transforming them from virtual to material with the click of a button.

What Are the Benefits of Additive Manufacturing?

Some of the many benefits of additive manufacturing include:

- Waste Reduction: Additive manufacturing utilizes about 98 percent of input material for a product.

- Energy Efficiency: Because fewer production steps and less material are required, 3D-printed products require up to 50 percent less energy than if they were produced with conventional processes.

- Design Flexibility: Layer-by-layer production allows for design of more complex shapes and enables the incorporation of varying printed materials with different design characteristics, such as stiffness and conductivity.

Growing Demand Across the Globe

The additive manufacturing industry is growing at a remarkable pace. In 2014, the industry saw a 35 percent growth rate, its largest increase in history, which amounted to a $4 billion global industry. Due to increased financial support and growing innovation, the global 3D printing industry has quadrupled in size in the past five years.

Bullish market projections indicate that the global additive manufacturing industry will grow by approximately 49 percent each year until 2019, or up to 300 percent within ten years. More conservative estimates predict that the industry will grow an average of 18 percent per year, reaching up to $7 billion by 2020.

Jobs from 3D Printing

Additive manufacturing skills are gaining momentum in engineering fields: over 35 percent of current engineering job listings require skills related to 3D printing. Jobs in the additive manufacturing industry demand a wide spectrum of skills, including engineering printers, manufacturing printing materials, and designing new software end uses for 3D-printed products.