What are Advanced Ceramics?

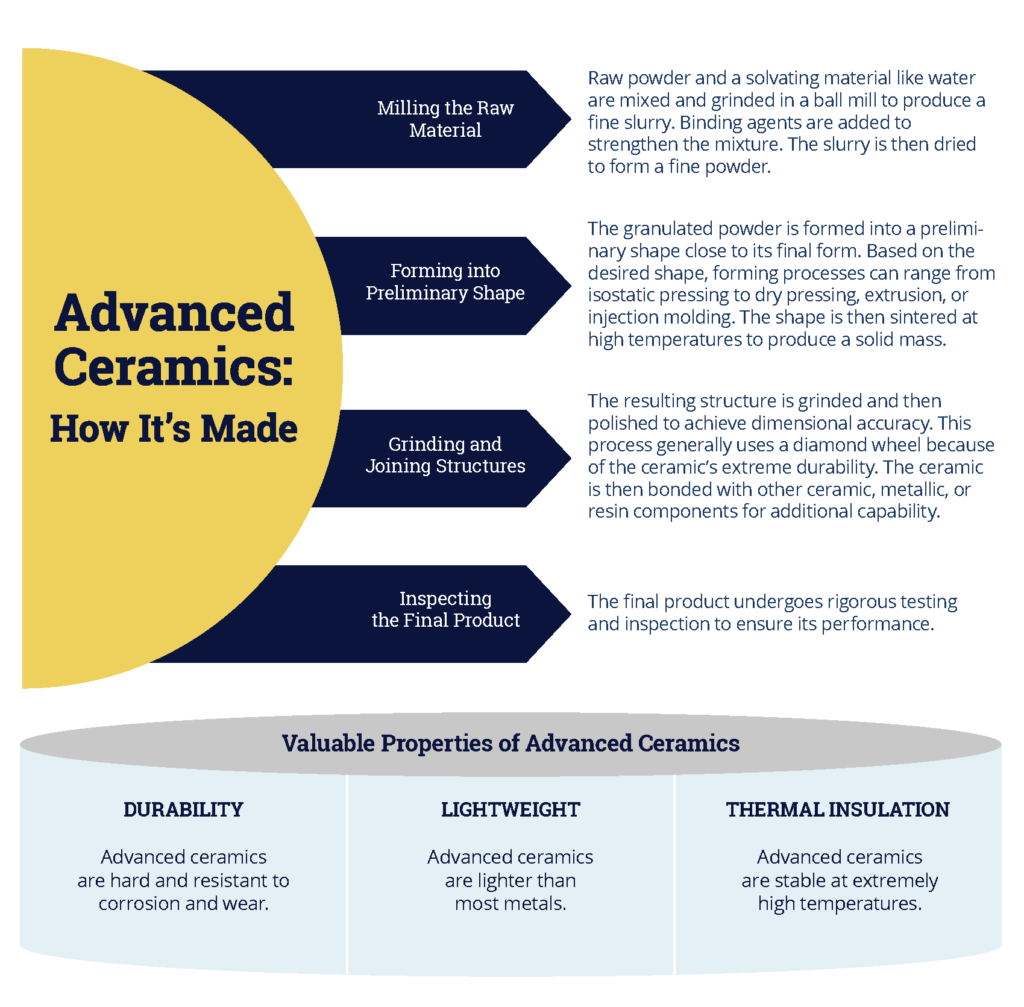

Ceramics are inorganic, nonmetallic materials that are formed by bonds between metallic and nonmetallic elements. Advanced ceramics are distinguished from traditional clay-based ceramics by their high technical and functional value, created with highly refined materials and controlled processes. Advanced ceramics are generally lighter than metals, have high corrosion resistance, and remain stable at high temperatures. These material properties make ceramics advantageous for commercial applications in the aerospace, defense, and electronics industries.

Ceramic matrix composites (CMCs) are refractory fibers embedded in a ceramic matrix, which creates a light, stiff, and super heat-resistant structure that is primed for high-temperature applications. In fact, CMCs can withstand temperatures up to 2,700°F. In the aerospace industry, use of CMCs in engine cores enable a 6 to 8 percent increase in fuel efficiency through reduced weight, improved durability, and reduced need for cooling. At the commercial level, GE Aviation advanced this technology with their silicon-carbide-based CMCs for jet engines and gas turbines at electricity generating sites.

Rising Demand for Advanced Ceramics

The global advanced ceramics market has a projected annual growth of 10.2 percent over the next eight years; the market is expected to grow from $56.7 billion in 2015 to nearly $134.6 billion in 2024. The North American market is the second largest in the world and its revenue is projected to grow by 9.5 percent per year from 2016 to 2024. Across ceramic product segments, CMCs will have the most rapid growth with an annual growth rate of over 13 percent up to 2024, and North America is expected to be the main driver of demand. In 2014, the United States topped global CMC demand, with U.S. demand expected to grow further by 11.5 percent annually until 2019.

Nationally and internationally, the major end-user markets for ceramics are the electronics, medical, and aerospace industries. In fact, electronic devices account for nearly 30 percent of the global advanced ceramics market, the largest application segment in 2015. Additionally, aerospace will continue to play a major role as CMCs grow; this top application segment is projected to grow by 14 percent each year between 2014 and 2019.

Opportunities for Innovation

Greater production and innovations can reduce the cost of material inputs and processing technologies. Although the cost of machining advanced ceramics for prototyping are comparable to non-ceramic materials, machining ceramics for production-quality structures can be expensive due to larger material inputs (ceramics cannot be easily prepared to closer tolerances) and the lack of customized grinding processes for different materials. CMCs also require energy-intensive manufacturing given the material’s high-temperature resistance. Ceramic fibers can be costly inputs for composite structures, but economies of scale will have a significant impact on lowering prices and facilitating market penetration.

Jobs in Advanced Ceramics

The advanced ceramics industry requires technical skills for materials development and application. Jobs in materials development may range from materials engineers to materials scientists and chemists while jobs in materials application include mechanical and electrical engineers, technicians, and industrial production workers.