What is Carbon Fiber?

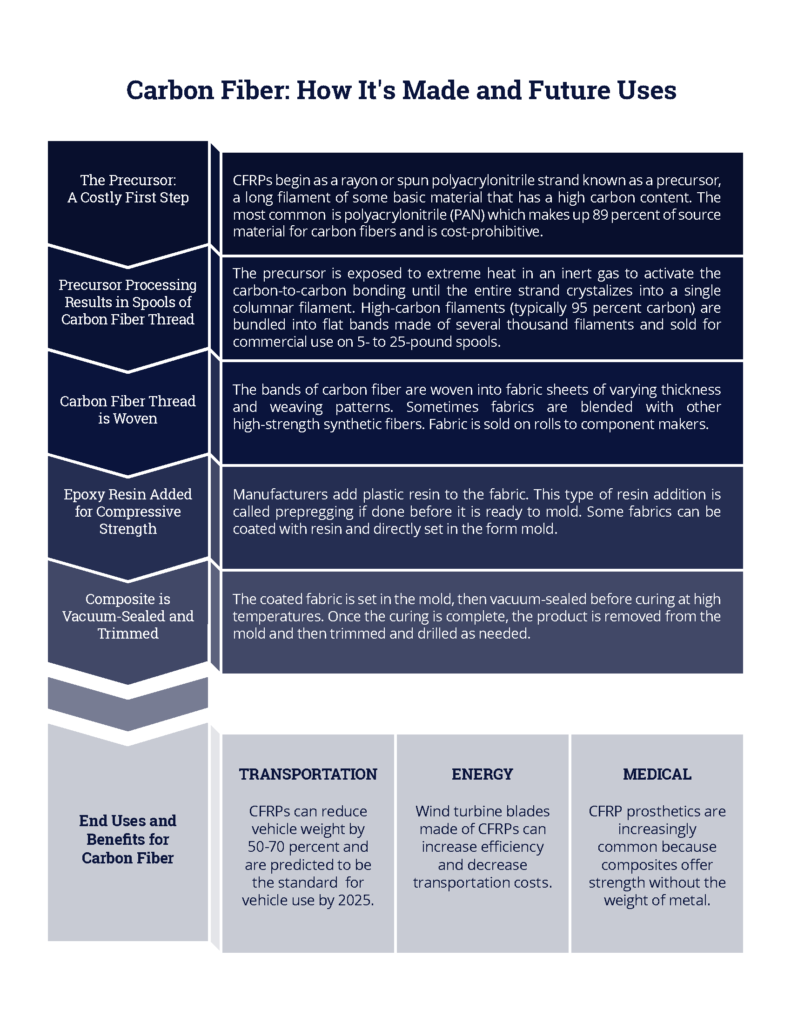

Carbon fibers are thin fibers composed mostly of carbon atoms, bonded as crystals in parallel alignment. This structure produces a strong, stiff, and wear-resistant fiber. Multiple fibers can be bound together as a tow to be used by itself or woven into a tough fabric. Carbon fiber can also be used in a composite structure, in which reinforcing fibers are embedded in a resin matrix to create unique structural properties.

Carbon Fiber Composites: Building Blocks for Efficiency

Carbon fiber composites, or carbon fiber-reinforced polymers (CFRPs), are five times stronger than steel and one-third the weight of steel. CFRPs’ ultra-lightweight and high strength properties enable efficiency in many technologies. For example, aircraft and automobiles have greater fuel economy due to decreased weight, and lighter, longer wind turbine blades can increase power output and ease transportation.

Rising Demand for Carbon Fiber

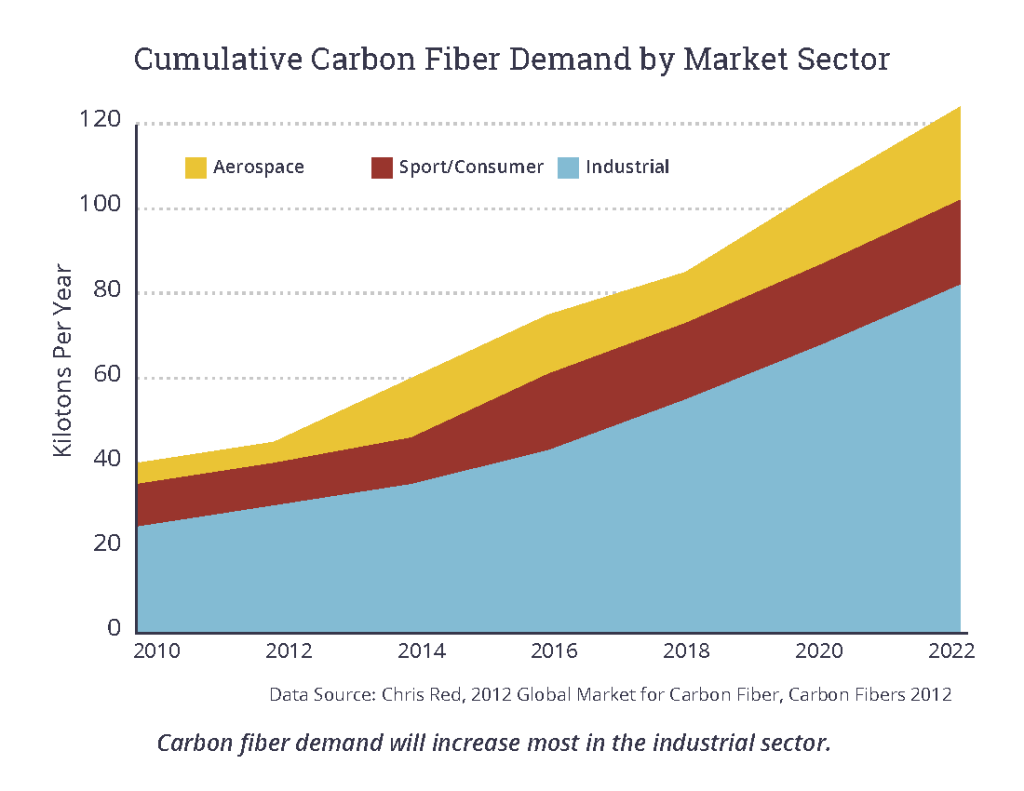

Global demand for carbon fiber and CFRPs is projected to grow at a rapid clip. The global carbon fiber market was valued at $2 billion in 2014 and is projected to grow at 9 to 10 percent per year until 2020. In 2015, the CFRP market was valued at $11.6 billion. Market reports estimate an annual growth of 10 to 11 percent between 2015 and 2020. In other words, the global demand for carbon fiber (including CFRPs) will double from 2014 to 2020, growing to over 100,000 tons. North America will remain the largest market due to its growing downstream industries and greater focus on lightweight aircraft and vehicles. In fact, North America was the largest consumer of CFRPs in 2014, accounting for over 35 percent of total volume consumed.

As global demand increases, the foreign export market is a significant opportunity for U.S. CFRP manufacturing. In 2015, U.S. carbon fiber exports totaled about $957 million and export opportunities continue to rise, with Germany and Italy as the top foreign customers. The top applications based on global revenues were aerospace and defense (50 percent), sports/leisure (11 percent), wind turbines (9 percent), molding and compound (8 percent), and automotive (7 percent).

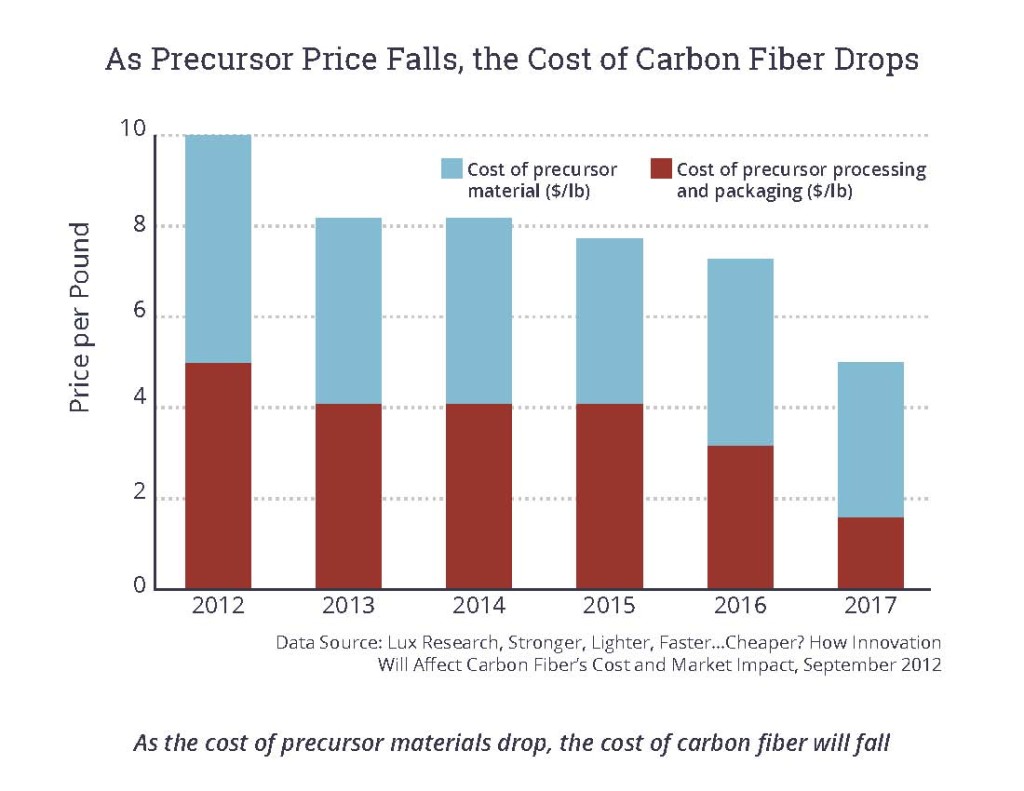

CFRP composites cost about $15 per pound, which can range from 1.5 to 5 times the cost of steel. While the cost of carbon fiber is more expensive than steel, CFRP composite vehicle owners will save up to $5,000 on fuel costs due to 50 to 70 percent weight reduction. Considering the life cycle cost of a good, such as fuel or maintenance, durable goods like vehicles and air transport may have lower life cycle costs when manufactured with CFRP composites, despite a higher upfront purchase price. CFRP vehicles could reach cost parity with steel-based cars if material costs are driven down to $4 per pound from their current price of up to $16 per pound. Although CFRP composite goods are currently relatively expensive, the cost of the material is projected to fall dramatically—up to 67 percent by 2030—as new research reduces the cost of input materials and manufacturing processes.

Jobs from Carbon Fiber

Jobs associated with carbon fiber are available at both large and small companies, which will create a demand for workers to design new end uses for materials, engineer more efficient manufacturing techniques, and manufacture the composite material. CFRP manufacturing is a sophisticated process, mostly done by technicians. Techniques to master include wet layup, resin infusion, laminating, cutting, trimming, and drilling. Knowledge in areas such as measurement, math, mechanics, fluid power and dynamics, electrical systems, chemistry, manufacturing processes and control, and lean manufacturing are key for industry professionals.